Following a discussion of rubber motor size for Bill Kuhl’s Wilbur, I did a series of flight calculations. I won’t discuss in detail how these calculations were done, many different versions are in the literature. I want to present the results and discuss in a general way the significance of motor sizing for flight performance.

For a given weight, motors are characterized by two parameters; length and cross section. Length times cross section equals volume, volume times the pretty standard density of our rubber equals weight. Thus motors of a given weight can be characterized by either of the codependent parameters, length being the most convenient.

Starting with a torque curve, motor weight, motor length, propeller revolution rate, aircraft weight, torque to fly level and sink speed, we can calculate incremental time steps and incremental altitude changes as the motor unwinds. We can add the increments together to calculate maximum altitude and duration of flight. These calculations are based on simplified assumptions, as nearly all theories in physics, yet they do produce a fairly realistic description of what I see in actual flights of the Dandiflyer, the subject of these calculations.

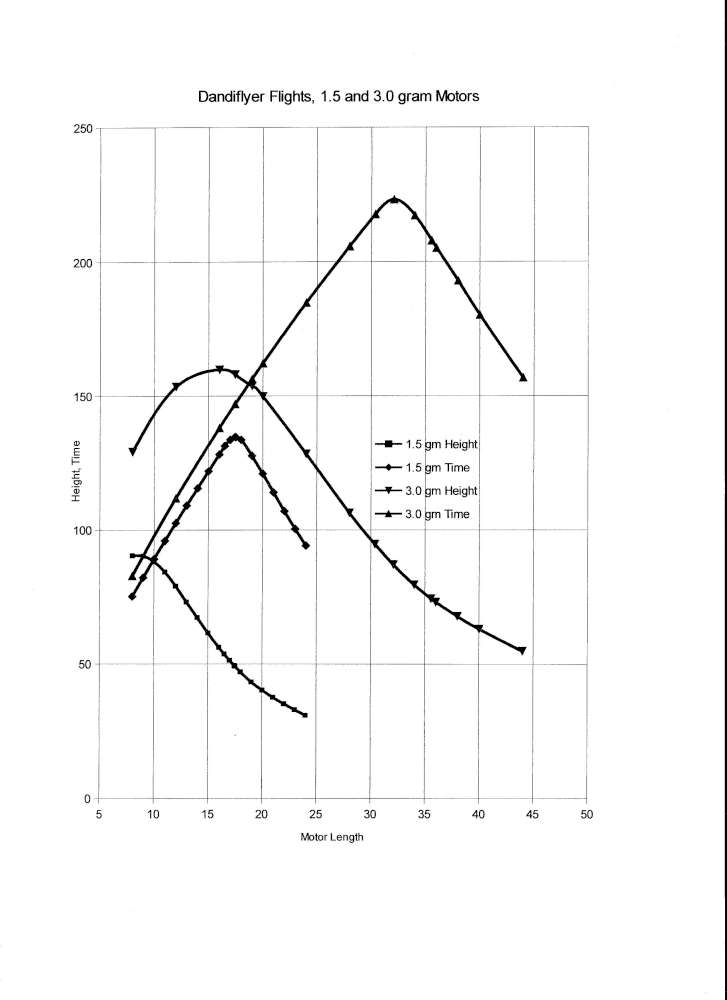

The above graph shows several such calculations for a 9.7 gram Dandiflyer with 1.5 gram and 3.0 gram motors with a range of motor lengths. The motor cross sections are inverse to the lengths. Height is in feet, time is in seconds.

Look first at the height and time graphs for the 1.5 gram motors, lower left quadrant. This is the weight of motor that comes in the kit, a 9″ loop of 1/8″. You notice that there is a definite best motor length for duration, and the graph falls off sharply on either side. This motor is 17.5″ long, not quite twice the 9″ space available between the hooks. Notice also that the shorter, thicker motor which reaches the greatest altitude has a very low duration and the best duration motor does not go very high. Best duration is not connected with highest altitude.

I design my motors to fly this maximum duration. I design on the assumption that the vertical lift is provided by the lift on the wings. I make the motor twice the available space because that is all it is practical to manage. Much longer than that and the motor balls up, sends out goobers, jams on the stick and does not unwind properly. The goal of duration requires a long, slow climb, a long, slow cruise and a long, slow descent. The defined weight of rubber contains a fixed amount of energy. To get the longest time, you must use that energy as slowly as possible. Power is the rate of use of energy. This implies you want to fly at the lowest power possible to remain airborne the longest time with the energy you have. Minimum power to fly is an important characteristic of the airplane.

Competition models fly with much more rubber than that. They climb nearly vertically on the propeller thrust. This computational model is not intended for that, but the 3 gram motor moves us in that direction. Again, notice that there is a definite best motor length for duration, and the graph falls off sharply on either side. This motor is 32″ long, much more than twice the 9″ space available between the hooks. This motor would be just about impossible to manage. Notice also that the motor which reaches the greatest altitude has a very low duration and the best duration motor does not go very high. Best duration is not connected with highest altitude.

Now compare the two duration graphs. Three gram motors of any length provide more duration than the 1.5 gram motor of corresponding length; the 3 gram motor graph is everywhere above the 1.5 gram motor graph. In particular, the 3 gram motor with the length of the maximum duration 1.5 gram motor gets quite a bit more duration, even though it is nowhere near the optimum length for a 3 gram motor.

Thus my conclusion that for competition models is, where the weight of motor may preclude optimum length, you at least make it as long as you can manage.

Gary Hinze Oct. 17, 2017