The following instructions are when you have the plan printed on tissue. You can Copy, Save and Print the plan. If you have the plan printed on copy paper, put the paper on a flat surface, cover it with clear film (like Saranwrap), then put the tissue you are going to build on over the plan. I suggest taping the corners to hold things in position. Then build following the instructions. The wood framing pieces are glued to the tissue right over the plan.You can print a plan on 8 1/2″ x 11″ tissue paper by taping tissue to printer paper along the leading edge. Cut the tissue to the same size as the printer paper. You can also cut the tissue 1/8″ longer than the printer paper, fold the 1/8″ over the edge of the printer paper and glue it to the back of the printer paper. Put the tissue on the side of the printer paper that takes the ink.You can also print and build directly on 8 1/2″ x 11″ onionskin paper.

- Single edge razor blade or model knife

- Wood glue (Duco or white glue)

- Glue stick to assemble sticks to paper

- Fine sandpaper or emery board

- 3 pcs 1/16″ x 3/32″ x 36″ balsa strip

- A 5″ or 6″ plastic propeller and bearing

- 1/8″ x 3/8″ x 12″ motor stick

- 1/8″ square by 5″ long balsa stick

- 8″ to 10″ loop of 3/32″ rubber for motor

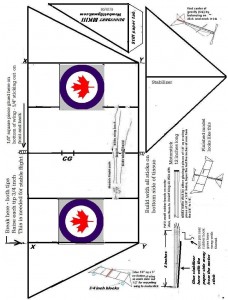

The paper of the plan may shrink in hot weather and warp the wing, so if you want you can wad it up into a ball (careful and don’t tear it), then smooth it out with a clothes iron set to cotton. This will break the fibers so that it won’t warp. Have something flat like an old ceiling tile or side of a cardboard box to build on. Put a bit of glue (or glue stick) on each corner of the plan on the face side (With that side up you can read the printing), then lay the sheet face side down on the building board, smooth it out, but don’t stretch it, and press the corners down. (If you are using “super glue” put some wax paper under the plan.) Now (be careful and cut to the right length) cut the sticks to fit on the lines of the plan. Wipe the glue stick carefully on the wide side of the stick and press it in place with a finger tip. I’d start with the front (long side) of the wing, then do the cross pieces and back side and tips. Do the same for Stabilizer and Rudder. The best way I’ve found to make the glue joints is to put a few drops of glue on a plastic bottle cap, then dip the end (or ends) of the stick in the glue before pressing it in place. NOTE: Do not glue the joints marked “X” or “Y”.

After all sticks are glued in place let the glue dry for a few moments, then using the razor blade carefully cut around the outside of each part, if you leave extra tissue, you can sand it off or trim it with scissors.

If you don’t have the 1/8” x 3/8” motor stick, you can make one from a 36” piece of 1/8” square balsa. Cut one each of 12”, 12” and 10” pieces from it, wipe a thin layer of glue on one side of each piece and glue together being careful to keep one end even. Then taper the back end starting at 5” from the back and ending at the end of the 12” piece, this is needed for the model to fly. If you have a 3/8” piece, taper one end starting at 5” from the end and taper down to 7/32” at the end. The tapered side will be the bottom of the stick.

The two blocks (a thick book will also work ) are to set the wing tips at the angle needed, a pic on the plan shows how. Use a bit of thread at each of the “bent” joints to strengthen them, the rest of the thread is to be wrapped around the rear hook, then cemented. Another way to stiffen the breaks on the wing’s dihedral joints is to cut bits of paper from the instruction sheet and glue them on the bottom of the joint instead of the bits of thread.

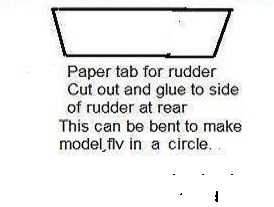

Now to assemble the model, put the stabilizer paper side down (sticks up) on the board, put some glue on the middle strip and put the tapered side of the motor stick on (the “slanty side” goes down) MAKING SURE IT CONTACTS AT BOTH FRONT AND REAR OF THE STABILIZER. Make sure the motor stick is square with the stabilizer, use something like a small clamp to hold it. Glue the rudder on the top of the motor stick, be sure it is square and straight. Put a small tab made from stiff paper on the back of the rudder (look on the plan for the place and shape). Find and mark the “CG” (center of gravity or balance point) as it shows on the plan. Slide the two small (orthodontic) rubber bands onto the motor stick, if the bands are small you may want to use 2 at each end of the wing mount stick. Put the wing mount on the top of the stick and use the bands to hold the wing in place with the “CG” marks lined up.

When making the motor, for the first flights, cut a strip just a bit longer than twice the rear hook to prop distance, tie the loop using either a square knot or an overhand knot. Whichever you use, wet the knot with saliva (nothing else will work here) before pulling tight, be sure to pull on all 4 strands equally and pull really tight. Be sure to lubricate the motor before trying to wind, baby oil, baby shampoo or liquid detergent will work but must be washed off after flying, then redone next time. I use a vinyl cleaner called “Son-of-a-Gun”, that doesn’t have to be cleaned off after flying.

When you fly the model, DO NOT THROW IT HARD, wind some turns into the motor, hold the propeller with one hand the model by the motor stick with the other, let go of the prop and GENTLY toss the model sideways to the wind.

Wind about 100 turns, if the wing is set as shown on the plan the model should fly fairly well, then you can adjust as shown on the wing. Don’t move the wing very much when making this adjustment, the model is sensitive to small changes. When the model is properly adjusted it should fly with the nose very slightly pointed up and not waver up and down or dive towards the ground. They usually seem to try and fly in left circles, you can make it fly tighter left with the paper tab on the rudder (I cut one from the instruction sheet and glue it with gluestick). With that short motor and hand winding probably 400 to 500 turns is maximum, be careful and don’t let the rubber jam up on the propellor hook, it can break . If you can rig a way to ‘stretch’ the motor while winding then it’ll take about 800 turns.

After you have properly adjusted the model with about 300 turns on the motor, then If the model “stands on its tail” when you release it with full winds (500 or over), gently twist the plastic between the stick and prop sideways in the same direction the model is circling, that should cure the problem.

Don’t be afraid to contact me (wombatt@gmail.com) if you have any question. If you want to build a different model, you probably won’t be able to buy anything locally, below are two companies that carry a nice line of good – not hard to build- models that are good flyers. I would not recommend trying to build a scale model of a real airplane until after you have built a few sport models as they are very hard to build

and get to fly.

These sites sell a good selection of kits by mail from easy to hard.

http://www.midwestproducts.com/

http://www.sigmfg.com/

Enjoy, Neil