8. October, 2011

I’ve had the Cloud Tramp ready to go for some time, after spending a couple weeks carving and testing five propellers, but the weather has not been good. Too much wind, then several days of rain. Weather forecast last night looked good, so I packed up this morning and headed for my larger field, about 20 miles away. It is about 1/4 mile wide and 1/2 mile long, with the prevailing drift along the length. Parked on the street and walked the half mile to the field, arriving about 8:45 AM, later than I’d like.

Clear sky, still air. Walked out into the middle of the star thistles that have taken over the field, stomped out a small clearing, got out a 33″ motor with 3 strands of 1/8″. Massaged the motor in a baggie of lube. Had a hard time getting the slippery O-ring onto the prop hook, needed to open the hook a little. Put in 2,300 turns, about 82%, for a start. As I was putting the O-ring on the aft hook, there was a pop and rattle. The knot had slipped out. In the ensuing struggle to get it back off the hook, the freshly lubed motor got away from me, hit the prop, bent the prop shaft and the bearing. After considerable flailing around of rubber, I got it off, straightened the shaft and bearing. I guess I need a better way to attach the ends of a three strand motor to the O-rings. Maybe I should use four strands of 3/32″ instead. As backup, I had brought along two used 33 1/2″ loops of 1/8″ from last year, test motors. Both had some minor nicks. I lubed one and put it on the plane.

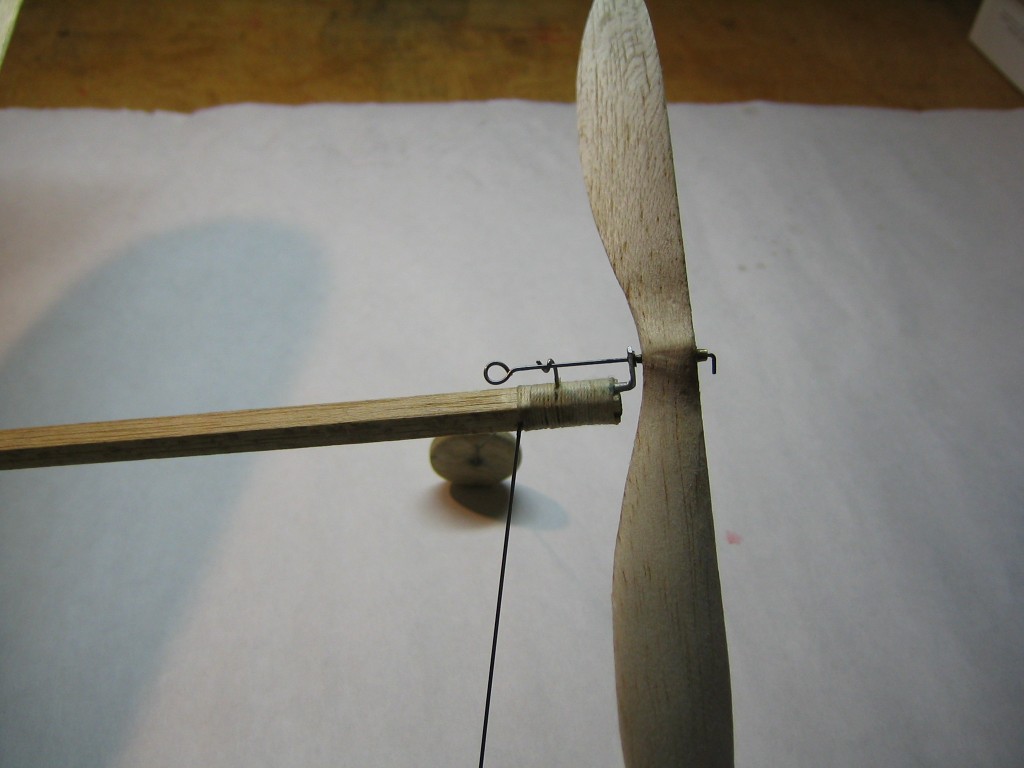

I have an O-ring at the knot in back, and another around the outside of both strands at the prop hook. It keeps the motor from coming off the prop hook when it goes slack. I put in 3,200 turns, about 92%. First launch stalled and hit the ground. I barely felt a little swirl of wind on my face. Zeroed the watch and launched again. Nice uniform right turning circles, climbing slowly, didn’t look like it would go high, but it did. With the pigtail rear bearing keeping the the prop shaft in line, the wandering in flight has stopped.

As it got higher, it began to drift slowly, gradually getting up to a moderate walking speed, later estimated to average about 3.4 mph.

That was about all I could keep up with, tromping through thick weeds. It was heading for the hills, forcing me to go through some tall weeds and painful star thistles. I was afraid it would go up on the hillside, or over the hills, but it started stalling and came down in tall weeds just short of the barbed wire fence along the foot of the hill, about a quarter mile from the launch.

Time on the clock was 4:25.44, the longest timed flight I have had with it. There was a wad of rubber jammed alongside the fin. That imbalance caused the stall and also prevented some turns from coming out of the motor. I went back out on the field, now about halfway down, farther out from the hillside. I could see some wind movement in the weeds. I started another windup, but the motor broke at 2,980 turns. Got out the second backup motor, lost the front end O-ring in the grass and had to salvage one from the other motor, then it broke at 2,220 turns. By this time, the weeds were in constant motion, there was enough wind to spin the prop. Time to go home, I don’t want to run over uneven ground covered by star thistles. Time was 9:30 AM. I didn’t get the number of flights I’d hoped for, but I got one great flight and learned a couple things. I will rework the rear hook to give the motor clearance from the fin. I may go with two strands of 1/8″, as it gave a good flight. The climb was slow and the motor continued to run for much of the descent, but it produced an excellent flight. Much more height and time in the air might become a flyaway.

Technical specifications. Weights: fuselage 12.4 grams, wings 8.6 grams, prop 1.9 grams, motor 4.6 grams. Balsa freewheeling prop is 8″ diameter and 1.8 P/D. The blade pattern is scaled from the plan. I have a 1/2″ x 2″ rudder deflected 1/16″ to give it a right turn, otherwise it rolls left into the ground on high torque. The wire-hinged rudder starts 1/2″ above the base and was originally intended to deflect left for a left turn.

As I walked along the creek on the way back to the car, several hawks came out of the trees and circled, gradually rising to a considerable height.

For more information about the Cloud Tramp annual memorial flight and postal contest, go here:

http://www.mikedparker.karoo.net/

For the plan and building article, go here:

http://www.mikedparker.karoo.net/plan.gif

http://www.theplanpage.com/things/ct/ct.htm

For the current Worldwide Postal contest, including a Cloud Tramp event, go here:

http://www.endlesslift.com/2011/10/20th-annual-worldwide-postal-competition/

Building a half size Cloud Tramp right from the half size plan is a fun project. It flies nicely indoors, as well.

Gary Hinze

Hey Gary,

I’m curious about that rudder hinge you made. Is it a piece of wire glued into groves? Is it copper wire?

Darcy

It is soft iron wire from a grocery tie. You remove the paper, roll it between blocks of wood to straighten it and cut it to needed length, in this case 1/4″. The fin and rudder are held down on the building board by pin clamps, with pins between the fin and rudder along the hinge line to space them slightly apart. A thin line of glue is applied on the wood across the gap and the wire is pressed into the glue. You can apply more glue on top to secure it. I have three pieces, 3/4″ apart. I put the wire on the left side, thinking I would want left rudder. It wanted right rudder. There was just enough gap to allow the small deflection needed. If I build another, I might put the wire on the right side. The rudder starts 1/4″ above the stick and is 2″ long. It is 1/2″ wide at the bottom with the hinge line perpendicular to the stick.

Rolling the wire between sanding blocks roughens the wire and may improve the grip of the glue.

Thanks Gary! This is a great idea!

I also figured out that pop can material works okay too. It can be cut to any strip width for different sized applications.

But the tie wire you’re talking about is even better! I will give it a whirl!

Another great article Gary! I have never had a flight that long on a rubber model outdoors without losing it. Too bad you had so much trouble with the rubber motors so as to not get in more flights.